Warehousing is a requirement for most businesses that involve storing an inventory. Regardless if you are a direct seller, a courier, or even a service-oriented business, at some point a well-organized warehouse is going to be a great asset.

For some, warehousing is seen as an unnecessary expense but contrary to that belief, a well-organized warehouse can boost productivity. Your warehouse gives you total control of your inventory and makes sure that your outputs are well organized and on time, which will consequently lead to bigger profits.

Various industries are highly dependent on warehousing practices. Depending on the current state of the market, warehousing protocols being adopted by companies can dictate the market values of products.

What Is the Importance of a Well-Managed Warehouse?

A well-managed warehouse will allow you to allocate, track, store, and put together an inventory more efficiently. It allows you to produce more while costing you a minimal amount of resources.

A well-managed warehouse will also improve safety within your business and keep the production line moving. This minimizes interruptions in your daily operations and helps your business scale.

While modern warehousing practices make use of technology to make your protocols more efficient, the most effective approach to warehousing is and will always be sticking to fundamentals.

These fundamental practices make use of basic logistical and engineering concepts to make your warehouse system more efficient.

What Is a Systems Engineering Approach?

Systems engineering is a field of engineering that deals with multiple engineering disciplines all working together. Think of a car, for example. You have an engine and steering, which are most often mechanical systems. You also have batteries and lights which deals with the electrical side. Systems engineering deals with all these multidisciplinary fields and makes them work together.

Your warehouse will incorporate multiple disciplines in order to function well. A systematic approach to warehousing means that you take every aspect of your warehousing protocols and find the best possible processes to make them work seamlessly.

Whether it’s logistics, storage, database management, or even clerical tasks; all these disciplines have to work together to make a better warehouse.

Steps to Having a Systems Approach to Warehouse Management:

In order to fully grasp the systems engineering process, it’s important that you understand these following steps. These are by no means a solution to all your warehousing problems, but by following these steps, you’ll be one step closer to a better-managed warehousing system.

1.Maintain a Linear Inflow-Outflow Process

A linear inflow and outflow process means that your stocks, inventory, or supplies approach each stage of the warehousing process once.

Often warehouse managers keep a very complicated process where an item moves from one station to another, and back again. This creates additional steps, making it inefficient and redundant.

Such a practice may also increase the possibility of errors in the system, thereby delaying the process even more and perhaps even halting warehousing operations altogether.

In order to implement a linear process, you first have to understand where your inventory is coming from, how they are tracked, how they are stored, how they are moved from one station to another, and how they get to their final destinations.

You also need to plan the stations these packages have to go through. Eliminate all redundant processes and maximize as many tasks as you can per station. If you can acquire inventory, input them in the database, and prepare for storage all in one station alone, do it. Implement Quality control checks at every station, that way your packages are always where they need to be. You can afford a 5-minute delay for quality control. However, you cannot afford to send that parcel all the way back to the bottom of the queue.

Remember your warehouse is one giant system, which means all the components of your warehouse have to work together properly.

The more redundancy you eliminate in the process, the better. This prevents wastage of time and valuable resources that are better off spent in making your company grow.

Inflow, storage, outflow. That is the general rule. If there ever is a process where your package has to go back to the previous step, you’re doing it wrong.

2.Proper Warehouse Organization and package Cataloging

This step is important as it helps you locate your parcels immediately. This also allows you to track your parcels and know what the status is and where it’s heading to.

Modern warehouses are very large with thousands of moving packages every minute. Without proper organization and cataloging, you may find yourself in a problem.

In the inflow and outflow process, we discussed that your packages should only make it to a station once. In order to achieve this, you have to be able to track your packages well. This is where proper organization and cataloging come in.

Each station of the warehousing process should know where the package has been, what the status is, and where it’s supposed to go. This makes it easier to understand warehouse operational efficiency.

Most companies make use of advanced and expensive inventory tracking software with bar codes, among others. While this may be a good option, they only really make your task faster by using computers. In reality, the logic behind these advanced systems is the fundamental practice of labelling and cataloging the packages well.

3,Maintain a High Level of Safety and Cleanliness

Just like a car that needs to be cleaned and free of elements that may cause damage, so should your warehouse. Every country has a specific warehouse safety regulation, but that doesn’t mean you should stop at the bare minimum to meet the requirement.

Nothing halts a warehouse operation quite like a safety crisis. If your warehouse has no safety protocols in place, such as racks that are sturdy and well bolted, fire safety features, and security systems, chances are that your warehouse will encounter such issues and halt your operations entirely.

Make sure you keep a safe and clean space for operations.You can also opt to invest in warehouse safety technologies that can increase the efficiency of your operations. This will not only allow your workforce to work with ease but also increase operational capabilities

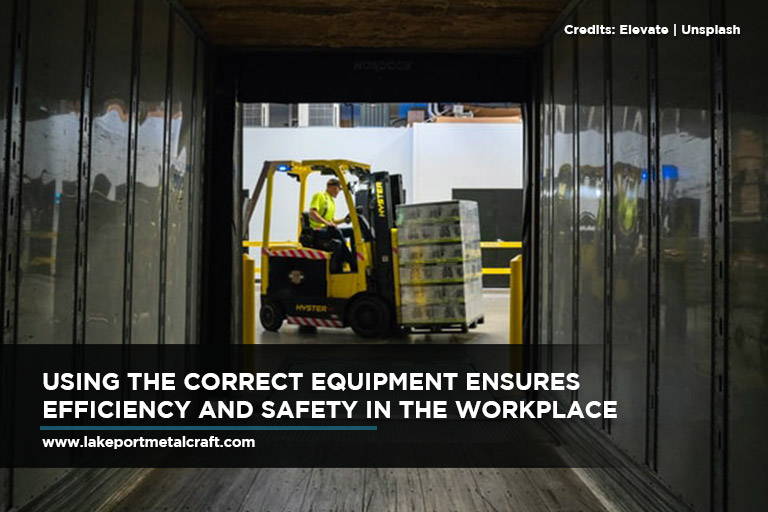

- 4.Have the Right Equipment for the Right Task

Make sure that you have the correct equipment for the correct tasks. If you’re in need of a capable forklift to transport heavy packages within your warehouse, get one.

Invest in the right equipment, that way you can perform the necessary tasks and keep the process moving.

Furthermore, if you have malfunctioning equipment, make sure to get it fixed. Your forklift cannot carry what needs to be transported if it has a broken fork.

5.Develop an ABC analysis for your warehouse process

No, it’s not an acronym. Instead, an ABC analysis means that you analyze which processes should come first, which should come next. That way you can create a smooth process without redundancy.

This will also help you understand which processes are a priority, that way you can allocate more resources for that step and realign the other stations of the warehouse to adjust.

By developing an ABC analysis, you can also understand how each part of your systems works with each other. This will help you iron out the creases and make your warehouse even more efficient.

Since this is an analysis meant to optimize your system, this has to be a constant effort. That way you can constantly improve your system.

6.Invest in Modern Technology

Every day, modern technology has made its way into the warehousing industry. Whether it’s to increase safety or efficiency, it is vital that you try to invest in these. As your operations increase, so should your capabilities.

Heavy equipment, automation, database storage for warehouse efficiency metrics, warehouse safety. All of these will help you achieve a more efficient operation and at the same time allow you to expand your enterprise as well.

As your company scales up and new technologies are added to the daily operation, it is also important to maintain a well-trained workforce.

7.Train and Retrain Your Staff Members

Your warehouse will not be run by you alone. The majority of the time, you’re going to leave much of the responsibilities to your staff.

Make sure that your staff is well-trained. That way they will not only know how to work the warehouse processes, but also find ways to improve this. Overall, depending on the size of your operations, your entire involvement in the warehouse process will be on a macro scale.

The personnel with first-hand experience and point of view regarding the many processes of your warehouse are your staff members. They are the ones who have a thorough understanding of how the process works

Additionally, your warehouse personnel are in charge of the operation and maintenance of your equipment. With a properly trained workforce, modern equipment can last longer and function better.

A well-trained and well-managed workforce should have a thriving ecosystem where everyone’s voices are heard.

Your warehouse plays a key role in your business processes. A well-managed warehouse can help ensure that your company scales and meets its productivity goals. A well managed warehouse adds efficiency, consistency and quality control to the process by helping you move goods at maximum speed, improving every stage of the fulfillment process.

If you’re looking to improve warehouse safety (along with your operational capabilities), turn to Lakeport Metalcraft. We offer The Backbone, a forklift rearguard that ensures the safety of your forklift operators. Call us at 416-587-5809 or email us at info@lakeportmetalcraft.com for your order.