What is Stand-up Forklift Underride?

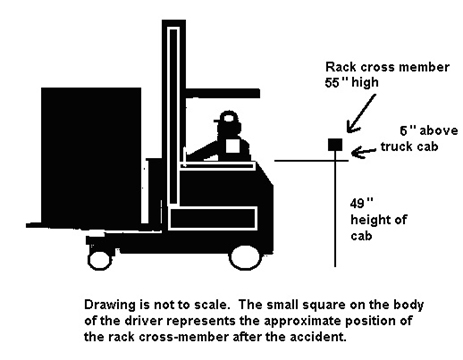

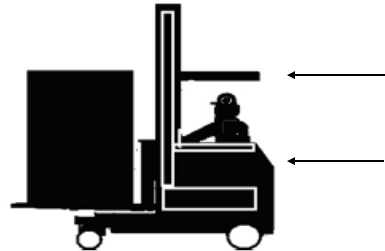

Stand-up forklifts and reach trucks are specialized forklifts used around storage racking in warehouses. Because of their design, they are prone to a hazard called underride. In Figure 1, you can see that the operator compartment is open at the back; there is no protective structure reaching from the overhead guard to the forklift body. The operator is exposed at the rear of the truck. If the forklift reverses into the racking, the forklift body can ride under a horizontal rack beam, crushing the operator between the beam and the front of the operator compartment. See Figure 2. To see a simulated underride accident, visit https://youtu.be/Q1sYmnANnis.

Figure 1

Reach truck. Note the lack of a

protective structure behind the operator.

Figure 2

Operator crushed between horizontal

rack beam and front of operator compartment.

Figure 3

Source: OSHA, Stand-up Forklift Under-ride Hazards, Safety and Health Information Bulletin, SHIB 07-27-2009

Types of Injuries Caused by Underride

Forklift underride can cause death and life altering injuries. These include:

Death

Paralysis

Chest Compression and Trauma

Asphyxiation

Internal Bleeding

Broken Ribs

Spinal Injuries

Fractured Vertebrae

Punctured Lung

Stomach Injury

Neck and Head Injury

Ruptured Spleen

Kidney Damage

Lacerated Liver

Contusions

Pelvis and Hip Injuries

Recommended Solutions by Safety Bodies

The US Occupation Safety and Health Administration (OSHA), in its Information Bulletin SHIB 07-27-2009, makes four basic recommendations to address the underride situation:

- If possible, make modifications to the shelving system so that the truck body or overhead guard strikes a rack cross-beam in the event of contact, stopping the forklift from reversing further. See Figure 4. However, this is almost always impractical, as the positioning of the rack cross-beams depends on the size and shape of the stock that is being stored.

- Purchase stand-up forklifts with corner posts, extended backrests, rear post guards or other protective structures.

- Install rear post guards on existing stand-up forklifts.

- Train employees to operate forklifts safely.

Figure 4

Set rack cross-beams at one or both or these heights.

ASME/ANSI/ITSDF* B56.1 Safety Standard for Low Lift and High Lift Trucks, the governing standard for forklifts, has recognized rear post guards as permissible since 1993 (Clause 7.30). CSA B335-15 (R2020) Safety Standard for Lift Trucks also recognizes the permissibility of Operator Compartment Guards (Clause 4.8.4.3), citing B56.1 Clause 7.30.

*ASME: American Society of Mechanical Engineers

ANSI: American National Standards Institute

ITSDF: Industrial Truck Standards Development Foundation

B56.1: The name of the committee.

The Underride Hazard Persists

A 2008 hazard analysis by the American Society of Mechanical Engineers (ASME) studied 3,000 stand-up lift truck accidents (categorized as pedestrian, maintenance, fall, collision, and stability accidents). As much as 58% (1,693 incidents) involved collisions between a stand-up forklift and a stationary object resulting in over 700 serious injuries and 22 deaths.

For a stand-up forklift or reach truck, the greatest hazard is an underride collision.

Even though the underride hazard has been known for decades, forklift manufacturers are still producing stand-up forklifts with unguarded operator compartments. In addition, there are legacy (used) stand-up forklifts in use today that have not been retrofitted to enclose the compartment. Ontario employees who operate reach trucks and stand-up forklifts around racking are at risk. Employees in jurisdictions outside Ontario have been injured and killed. The most recent incident we have been able to identify occurred when a 24-year-old worker was killed in January 2022 at the Santa Maria Industrial Park in Ramos Arizpe, Coahuila, Mexico. Two other fatalities we have been able to identify occurred in Valley, Nebraska, in September 2014 and El Paso, Texas in November 2019. (See Notes and References.) In a US court case, a lawyer representing an underride victim’s widow described the accident as “horrific” and “brutal”.

Addressing the Underride Hazard:

Stand-up forklift underride continues to be a hazard for employees who operate these vehicles around racking where rack components are not positioned to stop the forklift body from riding under a cross-beam. The result is that the operator can become pinned between a cross-beam and the front of the operator compartment.

Warehouses, distribution centres, storage facilities, “Big Box” stores and other workplaces with stand-up forklifts, reach trucks and racking should take the following actions:

- Management, employees and their safety representatives should conduct on-site assessments to identify underride hazards in their facilities.

- Management should communicate all potential underride hazard areas.

- Ensure all stand-up forklift operators are trained to safely operate such vehicles, with an emphasis on keeping a direct line of sight when travelling and looking toward the direction of travel at all times.

- Install protective rear guards to enclose the operator compartment. Every forklift should have a physical structure protecting the operator’s rear from objects outside the vehicle.**

**All protective rear guards installed must comply with the standards set out in ASME/ANSI/ITSDF B56.1 Safety Standard for Low Lift and High Lift Trucks, Clauses 7.29 and 7.30.

Notes and References

OSHA, Stand-up Forklift Under-ride Hazards, Safety and Health Information Bulletin, SHIB 07-27-2009.

ASME, Paper No. IMECE2008-66427, Hazard Analysis and Risk Assessment for the Operators of Stand-Up Forklifts, Published Online: August 26, 2009.

ASME, Paper No. IMECE2011-63944, An Analysis of Stand-up Forklift Accidents from the 1970’S to 2006, November 2011.

Zócalo (on-line journal in Mexico), Muere aplastado por montacargas en el Parque Industrial Santa Maria (Tr.: Man crushed by forklift in the Santa Maria Industrial Park), January 28, 2022.

OSHA Regional News Brief, Region 7, Worker fatally pinned by forklift at Menards warehouse, March 5, 2015.

KVIA.com, Worker dies after being pinned by forklift at east El Paso distribution center, November 13, 2019.

EHS Today, Jury Awards Widow $4 Million in Wrongful Death Suit, But Attorney Says She Deserves More, September 6, 2006.

For questions about this report, contact:

Norm Nopper

416.587.5809

norm@normnopper.com