Forklift underride collisions are among the most severe accidents in warehouses or any facility where reach trucks, and/or standup forklifts or counterbalance trucks are used.

Causes of Underride Accidents

Standup forklift and reach truck underride occurs during a collision where a horizontal rack beam intrudes into the operator cabin. If there are no barriers or objects that act as buffers on the floor (like pallets or stock) or at the level of the overhead guard, the forklift may back up further than intended resulting in a rear-ward collision. This may lead to the rack beam striking the operator or pinning them to the front of the compartment.

Potential Injuries in an Underride Accident

A rear-ward collision with a stationary object can result in the following injuries:

- Broken ribs – Besides the vertebrae, the ribs are also at risk of serious injury during an underride incident.

- Pelvic injuries – Injuries to the pelvis can occur during a crush accident.

- Internal organ injuries – A crushing blow can result in:

- Internal bleeding

- Punctured lungs

- Stomach injury

- Ruptured spleen

- Kidney damage

- Lacerated liver

- Head and neck injuries – These injuries include:

- Concussions

- Contusions

- Whiplash

- Skull fracture

- Spinal injuries – When an operator suffers direct contact to the spine, it can result in:

- Nerve damage

- Chronic pain – Up to 70% of spinal cord injuries cause chronic pain

- Broken bones – The vertebrae may incur fractures from a direct impact.

- Paralysis – Damage to the spinal cord can result in paralysis.

- Asphyxiation – If the upper body of the operator is pinned between objects, this can prevent them from breathing, causing suffocation.

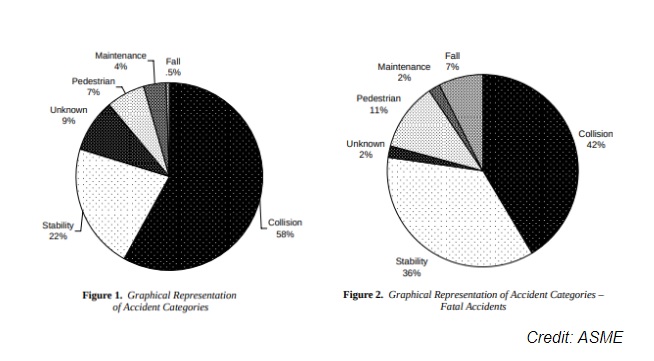

- Death – According to the 2008 ASME risk assessment mentioned earlier, collision accidents account for 42% of all fatalities across the six categories.

Injuries such as these will also have repercussions on the business itself. The company may face personal injury lawsuits or, in the worst case, possible wrongful death lawsuits.

By the Numbers

Most studies identify overturning or stability issues as the most significant hazard faced by a forklift operator. However, the research is based on sit-down forklifts which operate on an entirely different dynamic than a standup.

A 2008 hazard analysis by the American Society of Mechanical Engineers (ASME) studied 3,000 standup lift truck accidents (categorized as pedestrian, maintenance, fall, collision, and stability accidents). As much as 58% (1,693 incidents) involved collisions between a standup forklift and a stationary object resulting in over 700 serious injuries and 22 deaths.

For a standup forklift or reach truck, the greatest hazard is an underride collision.

The Burden of Responsibility

In place of the frequency and severity of injuries involved in standup forklift underride accidents, it may be surmised that manufacturers are putting in the effort to fix the problem. Unfortunately, this is not the case. While manufacturers clamour to address the stability issues of forklifts, little has been done to add further safety measures to prevent or protect the driver from rear-ward impact. This is in spite of evidence that points to the risk of underride collisions exceeding that of overturning when it comes to standup forklifts.

Organizations including the National Institute for Occupational Safety and Health (NIOSH), ASME, the US Department of Labor, Ministries of Labour in Canada, and other health and safety associations are making an effort to publicize and spread awareness of the dangers of underride. However, manufacturers do not see an issue with the forklift designs, believing instead that underride is caused primarily by problems involving the environment and the education of drivers. This effectively tosses the responsibility of preventing these incidents at the workplace and the operator.

Major forklift manufacturers suggest that avoiding the hazard can be done primarily through the careful operation of the vehicle, looking at the right direction, and maintaining control at all times.

The report published by ASME concludes with a recommendation to install an additional barrier, such as a rear vertical post on the forklift.

How to Prevent Forklift Underride

Underride collisions can be avoided by taking the following safety measures:

- Provide adequate training to operators. This is the first of many essential steps to take to ensure the safety of your forklift drivers. Forklifts are unique vehicles with their own set of risks. Make sure all forklift operators receive adequate safety training and certification.

- To emphasize on the previous point, do not allow staff without the proper training or certification to drive a forklift.

- Make adjustments to the rack shelf heights, so the forklift body or overhead guard strikes the rack in the event of contact.

- Install a stopper or barrier on the floor. This allows the forklift to strike the stopper instead of the shelf, preventing collisions.

- Attach a rear guard to the standup forklift or reach truck. The rear guard is a vertical post that extends from the forklift body to the overhead guard. It is designed to protect the operator from getting injured from horizontal intrusion collisions.

The Backbone® Safety Bar for Reach Trucks & Standup Counterbalance Trucks is a rear guard designed, engineered and manufactured by Lakeport Metalcraft Inc. to protect operators from the hazards of rear-ward collisions,

During its development, The Backbone was tested by a leading test, inspection and certification firm, and was found to be fully compliant with the ANSI/ITSDF B56.1 Standard to withstand impacts of up to 1.6 km/h.

It is easy to install and provides the missing physical barrier between the operator and objects outside the lift truck.

Lakeport Metalcraft Inc. distributes The Backbone® worldwide, through our affiliate dealers and resellers and directly from our factory. Users of The Backbone range from a major automotive manufacturer to big-box retail stores to aerospace companies. Contact us or one of our distributors for technical information or to make a purchase.