Despite their size and indoor use, forklifts pose huge safety threats if operated incorrectly. These common pieces of machinery are used everywhere from retail environments to construction sites. However, not every employee gets to drive one. Forklifts require in-depth knowledge and training to operate them safely. One wrong move or neglecting to notice a hazard can result in serious injury. For the safety of the operator and others on-site, reviewing these safety tips is a must. Here are ten tips to keep your workplace safe while using forklifts efficiently.

1. Ensure Operators are Certified

Each employee that needs to operate a forklift should attend in-person training and earn their certification. In this training, they’ll learn about the different parts of the forklift and how they work. Besides knowing how to drive it, they’ll learn how to balance loads and transfer loads from one spot to another. It’s crucial they learn about the various hazards to look out for, like puddles on the floor that could result in slipping. There are also specialized courses about different types of forklifts, like reach trucks and counterbalance.

2. Assess The Equipment Before Using

Before driving the forklift, make sure all its parts are functional and not damaged. Using any machinery with faulty parts could lead to serious injury. Check the brakes, controls, any warning signals, the mast, and the tires. Ensure the tires aren’t leaking air; this could cause your load to lean towards the deflated side and potentially fall off. If you do notice a strange warning button or damaged component, tell the supervisor on site right away. Forklifts that need repairs or maintenance shouldn’t be used until they’re in perfect working condition.

3. Wear The Right Safety Clothing

Most warehouse workers know that loose clothing is dangerous. It can get stuck in machinery, like forklifts, and result in injury. This also applies to wearing long hair down or wearing jewellery. In addition to those basics, forklift operators should wear proper safety gear. That includes high-visibility vests, closed-toed shoes, and hard-hats. When sitting in the forklift seat, always wear your seatbelt. It can be tempting to skip this last step out of convenience, but it’s one of the most important rules to follow.

4. Check Your Environment

Before turning the ignition, look around the forklift. Are there boxes sitting on the ground nearby? Is there a clear path ahead of you? A forklift is a substantial piece of equipment that can injure those nearby as well as the driver. Being aware of your surroundings is crucial. Notice the roadway signs around you. Follow the given speed limit, height limits, and weight maximums. If your forklift doesn’t meet the signs’ requirements, don’t try to test them. Lastly, never use a cellphone while operating a forklift.

5. Maintain Clear Visibility Always

How will you let others in the warehouse know that your forklift is on the move? Strategic use of the horn is one suitable way. You can also use your voice to yell or shout to nearby workers. Ensure your brake lights and other lighting systems are working, especially if you’re using the forklift in a darker setting. Don’t allow other workers to wear headphones where forklifts are being driven. They need to be aware of where the forklift is in relation to themselves. If your visibility is limited when operating a forklift, ask for assistance. Another worker who understands forklift operation can be your spotter and instruct you where to go.

6. Balance Your Load

The way you load your forklift is important. If the weight isn’t equally distributed across the forks, it could topple, or the load could fall off when you turn the vehicle. Keep the forks in a low position while loading and transporting. Don’t transport loads with the forks lifted in a high position as this increases the chances of toppling over. Use the proper securing tools for the load, like ropes and bindings. Also, make sure the palette you stock the load on isn’t damaged. If your load is tall and obstructs your view moving forward, drive the forklift in reverse with a bystander’s help.

7. Always Turn Off When You Exit The Vehicle

You may have to hop off the forklift for short moments to adjust the load or clear your path. Even though you’ll be returning to the driver’s seat right away, don’t leave the forklift running. This is an important safety tip that protects you and your fellow workers. It’s even more critical if you’re leaving the vehicle for longer periods of time. Turn the ignition off and take the keys with you. It can help to keep keys on a sturdy keyring so you don’t misplace them.

8. Say No to Unauthorized Drivers

Workers who aren’t certified to drive the forklift may occasionally ask to give it a try. While it’s admirable that they want to learn a new skill, practicing in an active workplace is not appropriate. They need to enroll in forklift operating training and get certified. If an unauthorized person asks to drive the forklift, say no. If you catch an employee driving the forklift when they aren’t certified, enforce consequences. An accident that results from a non-certified driver operating the forklift could mean lawsuits and expensive damage for the company.

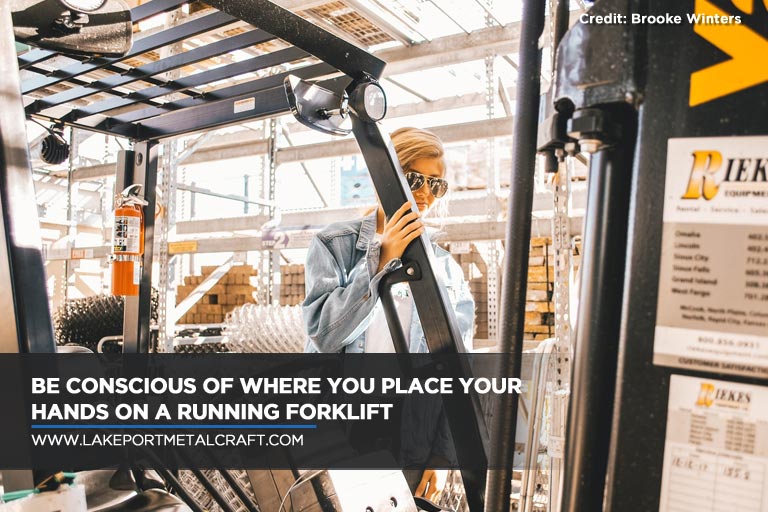

9. Beware of the Mast

The mast is the vertical belt at the front of the forklift that lifts and lowers the forks. When the mast is lowering the load, avoid touching it. Your hands and feet are prone to injury if they’re in contact with the cross members of the mast as it moves. Bystanders should also beware of the forklift when it’s in lifting mode. Incorrect operating could cause the load to drop or slide off. Anyone standing nearby could get injured.

10. Slow is Safer

Forklifts and other heavy machinery vehicles aren’t meant for high speeds. They require careful and stable movement. Most workplaces that use forklifts have speed limit signs to guide operators. No matter how comfortable you are operating a forklift, driving slow is always safer. Most models can reach speeds of 10 mph, but that doesn’t mean you need to reach that speed. Slow down as you approach corners and gradually make the turn. You want to avoid tipping your load, which is more likely to happen if you’re driving faster.

Bonus Safety Tip: Prevent Underride

Underride occurs when the forklift chassis drives or rolls under a shelf, rack cross-beam or horizontal obstacle, resulting in the object striking or crushing the operator. This hazard is specific to reach trucks and stand up forklifts, where the rear of the operator compartment is open, leaving the driver vulnerable to horizontal cross beams. Underride can cause severe operator iinjury—or even death.

There are over 85 forklift-related deaths in Canada each year. The best way to prevent underride is by installing The Backbone for Reach Trucks and Standup Forklifts. This ANSI-compliant safety bar is a bumper between the operator and horizontal crossbeams. It’s the best way to prevent injury from underride.

The Backbone® is manufactured by Lakeport Metalcraft Inc. For factory direct orders, contact Norm Nopper at 416.587.5809. You can also contact one of our dealers, Liftow, LiftTruck.com, and SUMOSafe.

To inquire about becoming a dealer or reseller, contact Norm Nopper at 416.587.5809.