Forklifts are one of the most useful and powerful vehicles on any job site. They are used to handle materials, carry heavy loads, as well as load and unload goods from delivery vehicles and safely secure goods in hard to reach areas.

The versatility of forklifts makes them indispensable, and it is no wonder forklifts can be found in most warehouses, factories, construction sites and anywhere heavy materials need to be transported and carried.

When it comes to different types of forklifts, there are as many options to choose from as there are uses for them. Here we break down the different types of forklifts and explain the benefits of each type to help you find the best forklift for your needs. It is important that all operators are properly trained on each type of forklift they operate.

Common Types of Forklifts

There are ten basic types of forklift, which include:

Warehouse Forklift

The Warehouse forklift can be found in most warehouses, factories and on job sites. It is one of the most commonly found working vehicles. It is usually characterized by three factors:

- Lift Capacity – which is the amount of weight it can safely carry without affecting its stability.

- Load Centre – this is the distance from the forks to the centre of gravity of the load you are carrying and can be very different depending on if you are carrying high or low, on your lift angle and your tilt angle. It is essential never to carry a weight that is over the recommended weight capacity of your forklift and to keep the load balanced.

- Stability – This is how your forklift remains stable even when carrying heavy loads. Forklifts use the machine weight to counterbalance the weight of the load and are designed to be stable as long as you stay within the recommended weight and height limits.

A warehouse forklift is excellent for loading and unloading delivery vehicles and can be used to carry inventory, lift pallets and move goods over short distances. They can generally carry the weight of one to five tons and work best in indoor locations.

Warehouse forklifts also have side categories of forklift, including:

- Side Loaders

Side loaders work great in narrow spaces and in hard to navigate areas where turning is difficult. The operator of the side loader stands in a sideways compartment. The side loader can move in close to the material, lift it and carry it in the same direction, without having to turn.

This manoeuvrability of side loaders makes them ideal for carrying long loads of hard to handle material such as lumber or long steel pipes that would be very unstable on a conventional forklift. They are not the best suited for handling standard inventory, so side loaders can mostly be found in steel manufacturing and lumberyards.

- Counterbalance Forklift

Counterbalance forklifts are what most people think of when they picture a forklift. The forklift can be driven right up to the load or rack with no extending arms. The forks stick directly out from the front of the vehicle, which makes it easy to grab inventory on and off of shelves.

The vehicle has a design that counterbalances the weight of the machine with the weight of the load and often has an extra weight at the back for more stability. Counterbalance forklifts can come in electric models, gas or diesel-powered. For electric models, the heavy electric battery powers the machine and acts as a ballast for the weight of the load.

Counterbalance forklifts also come in 3-wheel options, which allow the driver to turn easily in circles.

Stand up counterbalance forklifts make it safe and easy for the operator to get off and on the forklift in between loads.

Telescopic Forklifts

These are sometimes known as a reach forklift or teletruck. Telescopic forklifts are like a combination forklift and a crane. They have a boom and an extending arm that allows them to reach far into the back of delivery trucks and lift materials much higher and farther than conventional forklifts. Many teletrucks can lift heavy loads to 55 ft in the air.

Industrial Forklifts

Industrial forklifts are also known as large capacity forklifts, and they can lift loads that are much heavier than standard forklifts and lift them much higher. Most industrial forklift models start with a maximum weight of 30,000 lbs, but they cannot reach or lift at awkward angles as a teletruck can.

Rough Terrain Forklifts

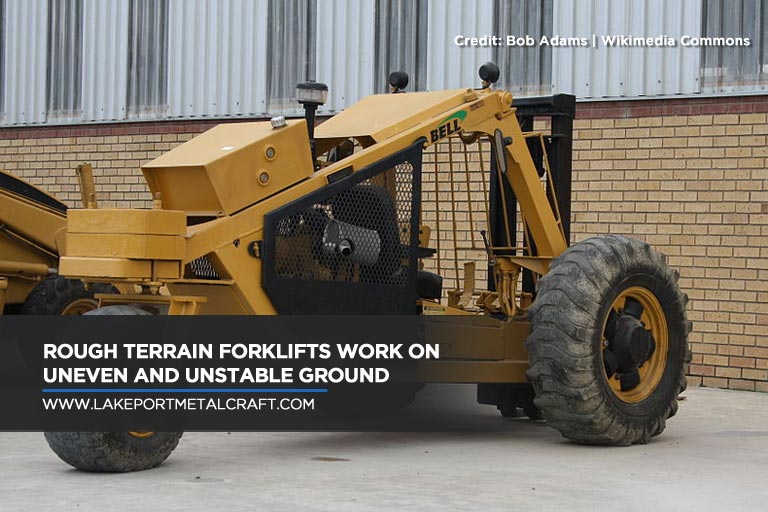

Rough Terrain Forklifts are generally designed for use outdoors or on uneven, unstable surfaces. They have thick tractor style pneumatic tires that won’t slip on wet or slippery surfaces or be punctured by nails or sharp rocks. These tires also help with stability when carrying heavy loads on uneven ground.

Rough terrain forklifts are often used in lumberyards or in construction sites that require lifting to high elevations. They can have a traditional straight mast or a telescoping mast for even greater reach. They can handle a weight capacity of 6,000 to 12,000 pounds or more.

Reach Trucks

Reach trucks are designed to be used in warehouses, and their name comes from their ability to extend their forks out beyond their stabilizing legs into racks. They work well in tight spaces and can maneuver in warehouses with narrow aisle ways and lift loads to high heights (over 10 metres).

Reach trucks have very low clearance and are most suited to working indoors on flat and even surfaces. Because reach trucks have heavy electric batteries and stabilizing legs, they do not need counterbalance weight to remain stable.

One common injury to reach truck operators is a rear collision with the warehouse racking. This injury can happen because most reach trucks have an open back with no barriers between the operator and the racks. One way to prevent these injuries is to install a safety device called The Backbone® on your reach truck.

Pallet trucks

Pallet Trucks or sometimes called pallet jacks or pump trucks, are typically non-powered tools for moving loads on pallets. They are easy to use and can fit well into small tight spaces where other types of forklift would not fit. They are not suited to lifting loads very high as the pump truck only raises the pallet enough to clear the ground.

Pallet trucks can lift loads up to 3.5 kilograms and do not require specialized training to operate. The operator slides the forks underneath the pallet and pumps the handle to raise the pallet off the ground. Pallet Trucks are also relatively inexpensive to buy or rent.

How to Choose A Forklift

If you are looking for a forklift, it is important to understand how it will be used and what is required. There are forklifts designed for every job and location, and it is essential to know what you need. Some things to consider are:

-

- Capacity – What weight do you need to lift? How high do you need to lift materials?

- Space – how large is your area, how high are your doorways and openings?

- Power – Will you need to run on electricity or gas?

- Surface – is the ground even or rough? Will you need your forklift inside or outside?

If you are considering purchasing forklifts or reach trucks for your operation, it is also important to consider the safety of your forklift operators. Forklift dealers and companies often do not provide the forklifts they have for sale with underride protection. Contact Lakeport MetalCraft Inc. and ask about The Backbone®, a safety device you can install on your reach truck to prevent rear collisions. To learn more about The Backbone®, call Lakeport MetalCraft Inc. at 416-587-5809.